Services

We pride ourselves on delivering precision and excellence in every project. With over 14 years of industry experience, our team specializes in advanced cutting and fabrication techniques, serving a wide range of materials including metal, wood, and acrylic.

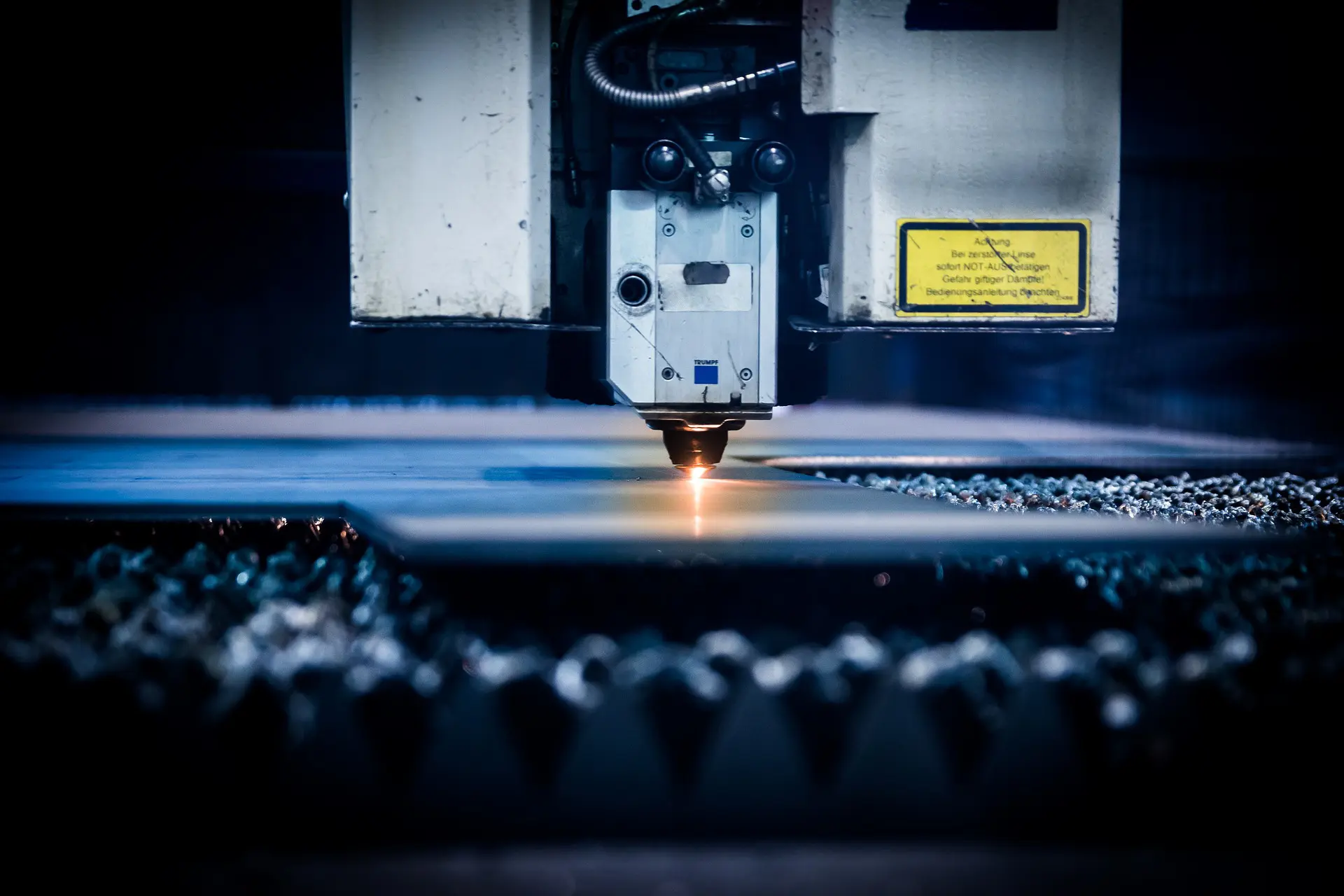

Fiber Laser

Able to cut multiple types of metal with extreme precision up to a 5’X10′ footprint

Routing

Able to work with wood and acrylic as well as in 2D and 3D modeling

Plasma Cutting

Geared towards production parts or pieces that don’t require as much precision as laser or waterjet

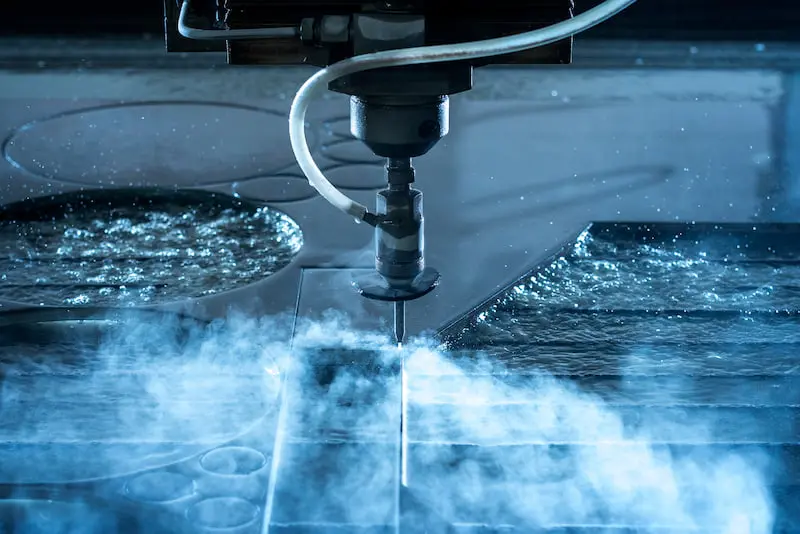

Waterjet

Able to cut in multiple medias such as steel, stone, and acrylic.

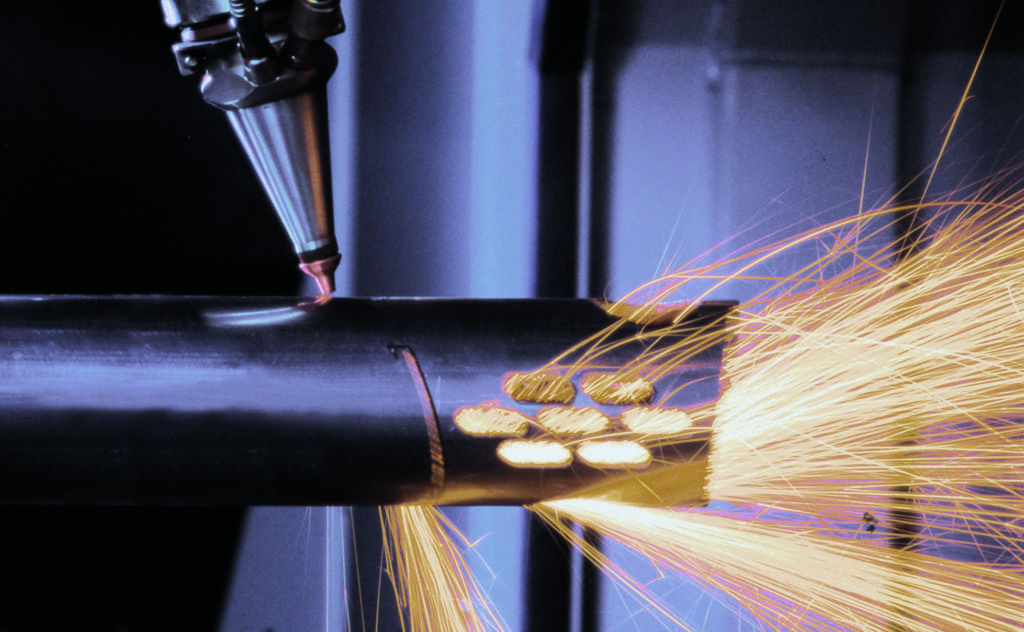

Tube Cutting

Able to cut square, round, and rectangular tube in diameters up to 8 inches

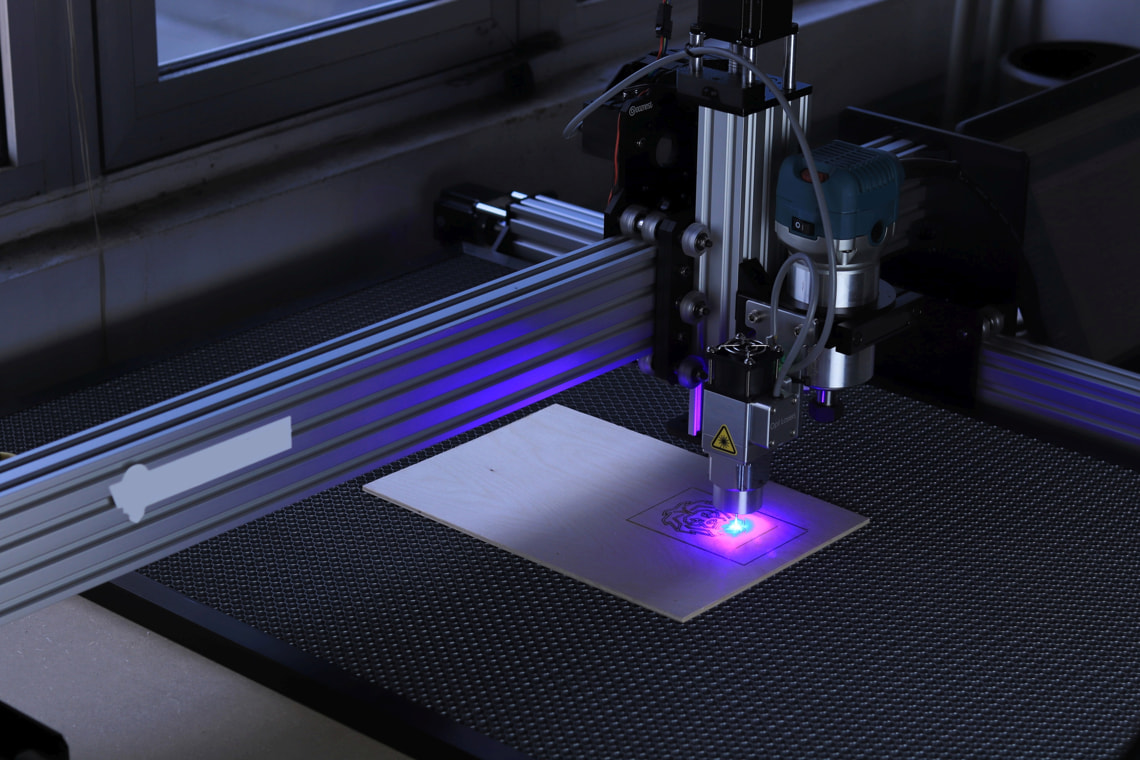

CO2 laser cutting

Can etch and cut into acrylic, and able to etch into glass and flat or curved surfaces.

Engraving

Can engrave serial or part numbers all the way to logos, images, designs, and far more.

Designing

Can take any concept or idea and be able to transfer it into workable formats such as solidworks, fusion 360, autocad, and much more

Fabrication

We can handle all types of welding such as MIG, TIG, arc, or stick. Were also able to assemble, polishing, and finishing from one of a kind to mass production.

Installation

In most cases we can go to the work site to install or products where and when it is required.

14 Years of Expertise

Questions & Answers

We aim to make your experience smooth and informed.

What types of materials can you cut with your Fiber Laser?

We can cut a variety of metals with extreme precision using our Fiber Laser, with a footprint up to 5’x10’. This includes materials like steel, aluminum, and stainless steel.

Can you assist with design work for my project?

Yes! We can take your concept or idea and transform it into workable formats using software like SolidWorks, Fusion 360, and AutoCAD, ensuring your design is production-ready.

Do you offer installation services for custom products?

Absolutely! We can install custom products on-site where and when required, ensuring everything is placed perfectly and meets your needs.

What’s the difference between plasma cutting and waterjet cutting?

Plasma cutting is ideal for production parts that don’t need the same precision as laser or waterjet cutting, while waterjet cutting is more versatile, able to cut materials like steel, stone, and acrylic with extreme accuracy.